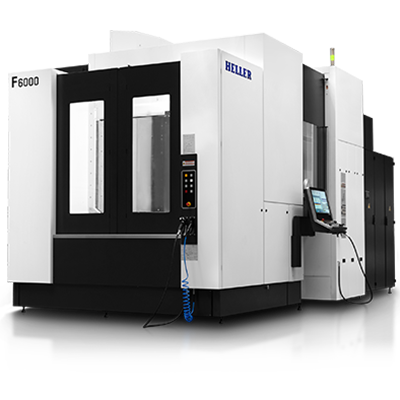

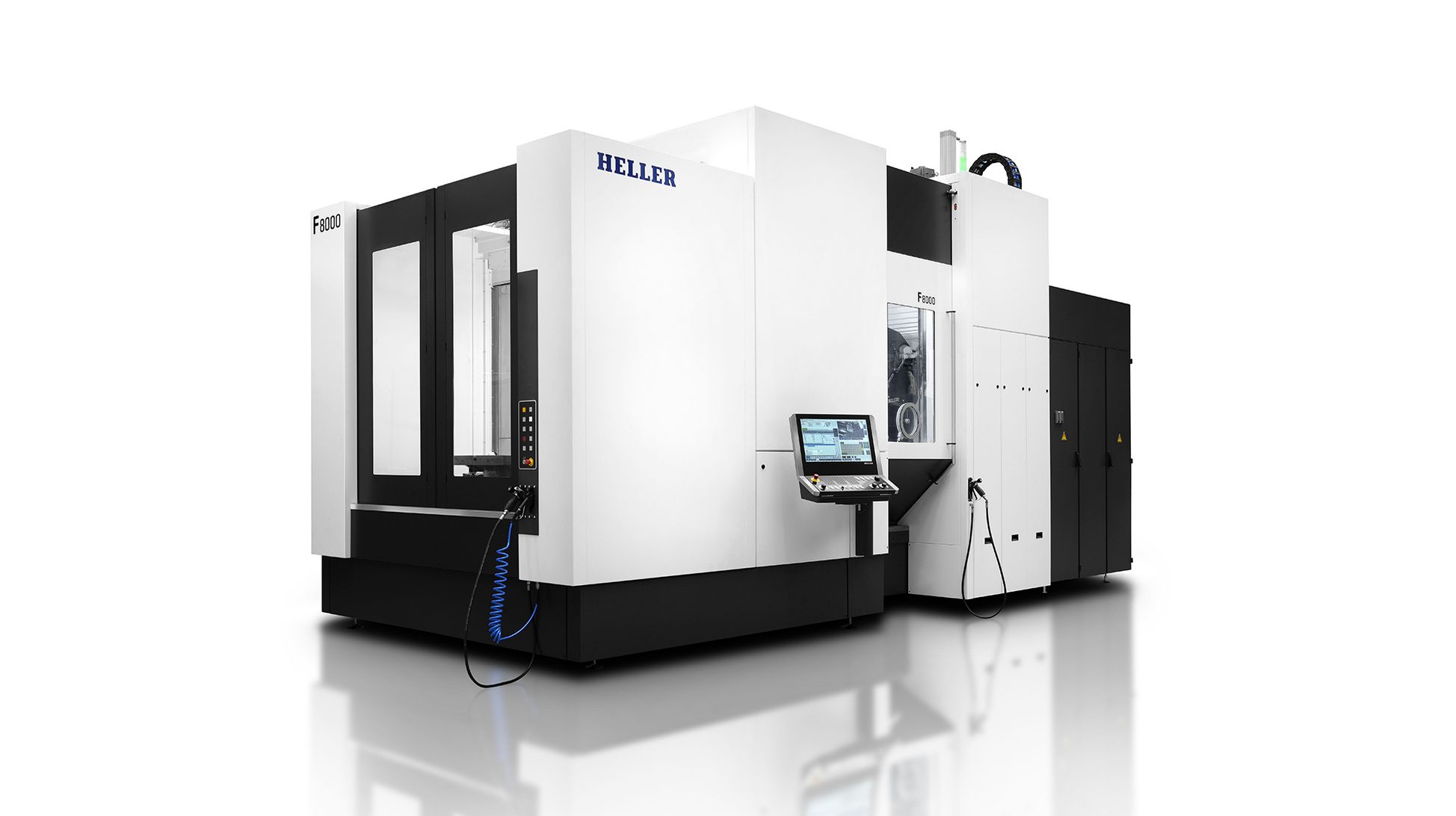

Following the successful introduction of the F 5000 and F 6000 models, HELLER is now extending its new generation 5-axis range at the top end with the F 8000. With numerous innovations that ensure extremely high performance and precision, as well as a small footprint, the F 8000 is suitable for applications in a wide range of industries. The new high-performance machining centre has been on the market since September 2024.

Things move fast at HELLER: In the autumn of 2023, the Nürtingen-based machine manufacturer unveiled the F 6000, the first 5-axis machining centre in its new generation F series. Only six months later, another model was launched: the F 5000. And the larger F 8000 has been available since AMB 2024 in Stuttgart. Like its ‘siblings’, the machine is suitable for a wide range of users in many industries, from mechanical engineering and power generation to aerospace – from single-part manufacturing through to flexible 24/7 series production.

The F 8000 is based on the successful 5-axis F series, which has been on the market for more than a decade. However, it surpasses its predecessors in many areas. For example, at 4.20 metres wide, it has a much narrower footprint and the basic version takes up around 25 per cent less space. In addition, the optional PRO version offers the best technical specifications. Axis acceleration in X/Y/Z has been increased by 50% to 6 m/s2. Chip-to-chip time has been reduced by approx. 30 per cent. The F 8000 with PRO package also offers greater precision. Positioning tolerances in X/Y/Z are 6μm – a 25% improvement over the previous model.

Another advantage of the new F 8000 is its large work envelope (X/Y/Z: 1,400/1,200/1,400 mm), which allows larger workpieces to be machined and, above all, the 150 mm longer stroke in the X-axis, which provides even greater machining flexibility. In addition to 800 x 800 mm pallets, it is also possible to use larger 1,000 x 1,000 mm pallets. Head of Development Dr Manuel Gerst explains: “The maximum pallet load is 2,000 kg. And from the end of 2024, we will offer an optional pallet load of up to 3,000 kg.”

Full compatibility with the previous generation

To make the transition to the new generation F series as easy as possible, HELLER has ensured maximum consistency. This means, for example, that the pallets and tools are fully compatible with the previous 5-axis range.

The new machine is equipped with the latest generation Siemens control system, SINUMERIK ONE. However, users can easily adopt all NC programs used on previous machines equipped with Siemens’ SINUMERIK 840D sl control. A main operating unit in console-design with a 24-inch touch screen and a host of other features makes the new control system even more enjoyable to work with.

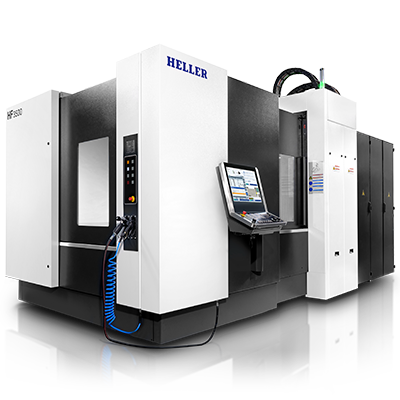

With the new F series, HELLER not only guarantees full continuity with previous generations. The developers have also ensured a high level of compatibility with the new H series 4-axis machining centres. Pallets and tools are interchangeable, and standardisation of structural components such as beds and columns enables the same strokes, pallet loads and part dimensions.

Small footprint provides more space for automated machining

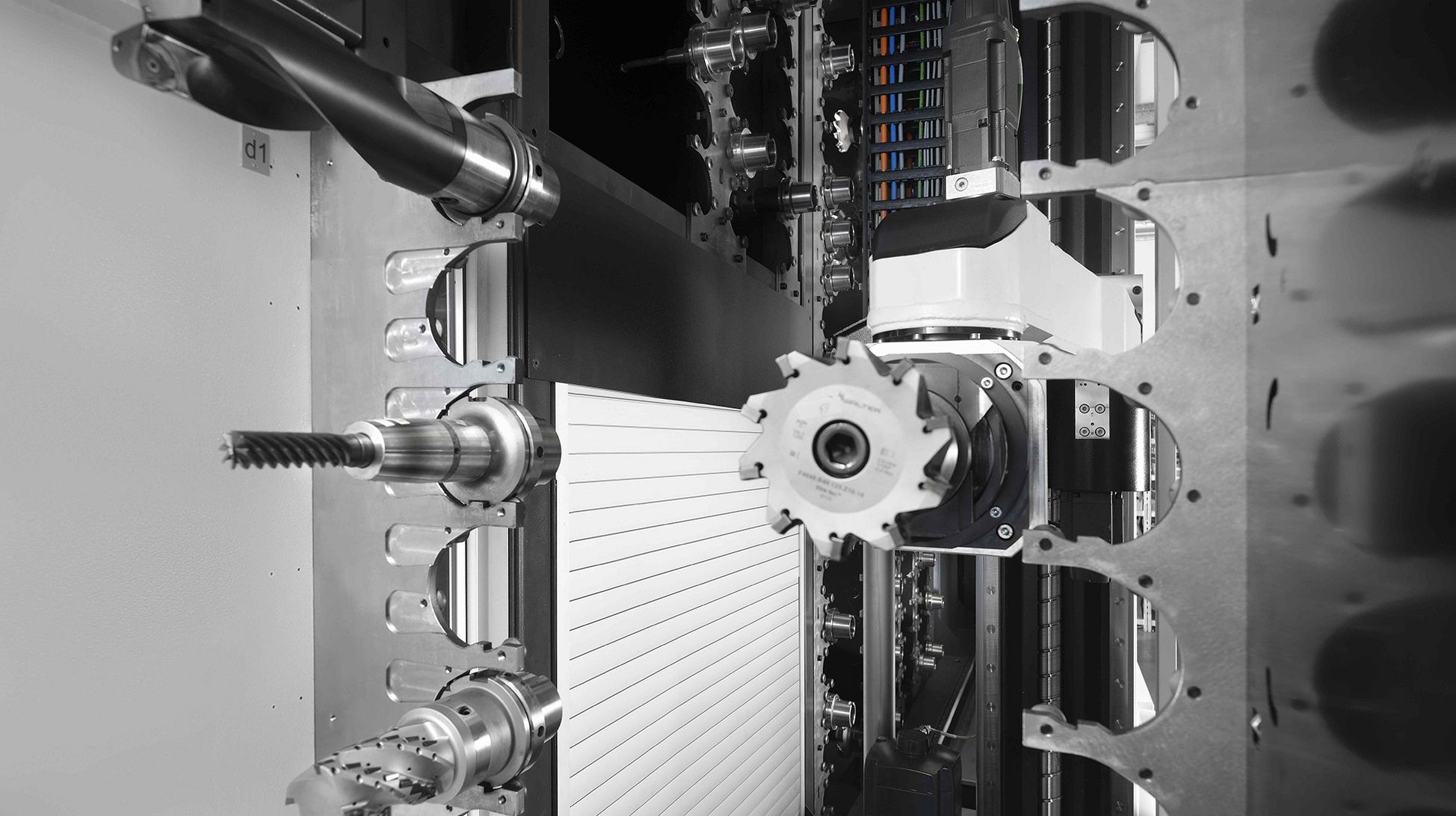

The standardisation of the 5-axis machine within the range goes even further. The F 8000 uses the same modular system as the entire F series for key components such as heads, spindles and tool magazines. The machine structure is also standardised across the F series, resulting in the narrow footprint mentioned before.

Equally important to the compact design of the new F 8000 are HELLER’s new rack-type tool storage systems. All of them are almost two metres narrower than the previous versions. This is particularly useful when automating multiple machining centres. Four machines can now be placed in a row where previously only three could be installed.

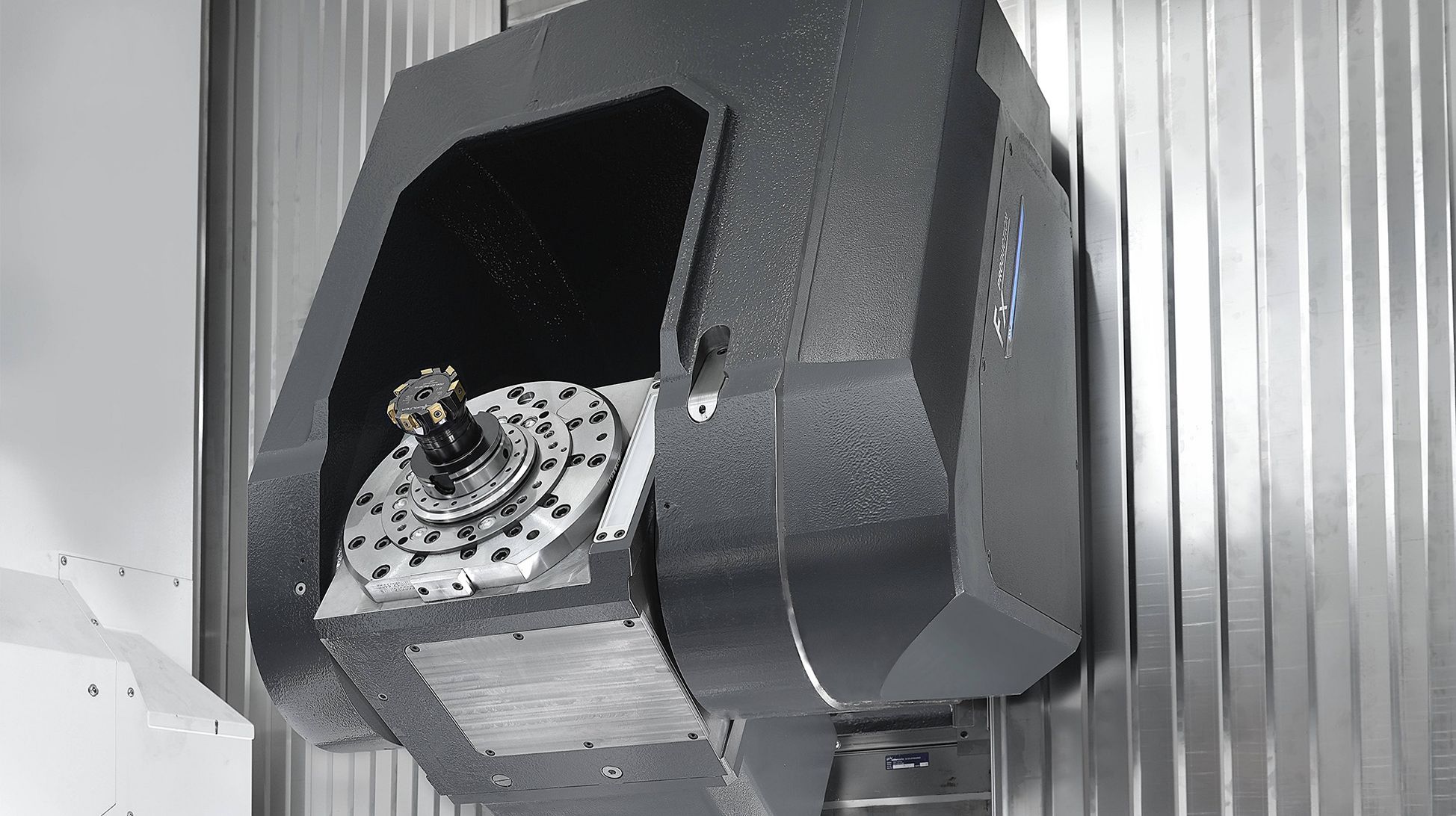

Machining units with tilt and swivel kinematics

Among the highlights of the F 8000 – and the new F series as a whole – are the completely redesigned swivel heads, which ensure maximum cutting performance. The integrated motor spindles, developed in-house, are manufactured by HELLER. Equipped with an HSK-A 100 interface as standard, the Dynamic Cutting Universal (DCU) unit achieves torques of 400 Nm and speeds of 12,000 rpm. The Speed Cutting Unit (SCU) provides 15,000 rpm with HSK-A 100. In conjunction with the optional HSK-A 63 tool interface, HELLER also offers spindles with speeds up to 18,000 rpm. For ultra-heavy machining, the Power Cutting Universal (PCU) unit with gear spindle is still available – delivering 1,146 Nm of torque and speeds up to 8,000 rpm.

In addition to the swivel heads, HELLER also offers a tilt head variant for the F 8000. It is characterised by a particularly high degree of flexibility in 5-axis machining. This is because the tilt kinematics make it possible to produce the recesses and undercuts required, for example, in the manufacture of integral components for the aerospace industry.

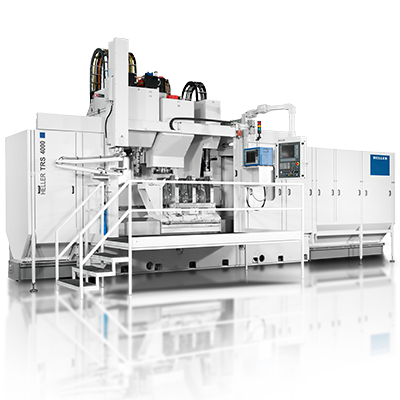

Ready for any type of automation

Whether it is for the manufacture of single parts or flexible series production, the F 8000 5-axis machining centre is always the right choice. For those who are not yet sure whether they want to equip the machine with pallet automation at the time of purchase, HELLER offers the ‘Automation-READY’ option for maximum flexibility. This means that the available standardised automation systems can be integrated quickly and easily at a later date. The F 8000 is equipped with an automatic pallet changer as standard. In addition, extended automation with linear or rotary storage systems or robots is available.

All in one – milling, turning and other technologies

In addition to automation, complete machining is playing an increasingly important role in many manufacturing companies. Following this all-in-one concept, HELLER offers an optional mill-turn function for combined milling and turning operations for the entire F series. At its heart is the high-torque DDT (Direct Drive Turning) rotary table. This means that in addition to milling and drilling, external and internal contours can be turned longitudinally or transversely in a single set-up, as well as a wide variety of undercuts and recesses. Even cutting of external and internal threads is possible. This eliminates the need for reclamping on separate turning machines, improving part accuracy and reducing cycle times.